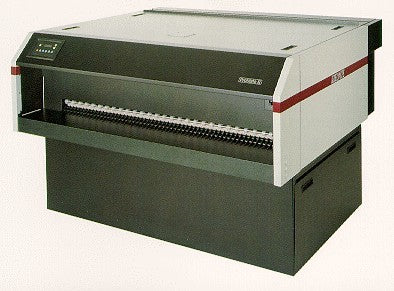

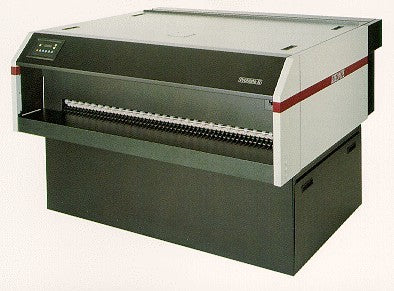

ProMate II Processors

For Pricing Email or Text

For Pricing Email or Text

Inventory

Inventory

Photos represent what we have or what we have sold.

Please ask via email, text, or WhatsApp.

Description

Description

The ProMate II is a series of high performance tabletop color and black and white print processors. Possessing many features of larger, more costly floor model designs, the ProMate II is compact in design and economically priced.

The ProMate II offers these energy saving features:

- Seamless one-piece thermoplastic tanks reduce condensation and heat loss from tempered chemicals. Less power is required to maintain accurate chemical temperatures.

- Tempered water is not required in the stand-by mode.

- Dryer, water, and transport system start automatically and turn off when not required.

Computer Precision and Control

With computer precision, the ProMate II automatically controls temperature, development times, and replenishment rates, assuring a high degree of processing accuracy. Chemical temperatures can be programmed to within 1/10 th of a degree F, development times can be programmed to the second, and replenishment rates can be adjusted to the milliliter. Processing parameters are continuously checked, adjusted and re-checked by the computer, maintaining process control with unmatched precision.

Keyboard Controls

The ProMate II keyboard is designed for easy data entry. You can easily switch from processing color prints to Duratrans(tm). A 32-character alpha-numeric display instantly verifies operator input and processor status. Audible signals will alert the operator of processor status, and any processing parameters that may be out of tolerance.

Modular

Tanks and transports are modular in design, reducing the chance of obsolescence when processing specifications change.

Standard Features

Advanced Replenishment System

Infrared sensors on the feed table of the ProMate II detect material entering the processor. The computer constantly monitors the amount of material being processed, and activates metering pumps for the proper amount of replenishment.

Seamless Tanks

The ProMate II’s deep tank design reduces chemical surface area, minimizing chemical oxidation rates. Kreonite tanks are warranted for 10 years. Reliable Transport System

The ProMate II is designed with Kreonite’s proven socked roller transport system. This design uses a “soft against hard†roller design which provides uniform agitation and an efficient squeegee action. Kreonite transports require little maintenance and snap-in retainer clips simplify disassembly for cleaning. This transport system has been in use worldwide in thousands of Kreonite processors for over 25 years.

Efficient Dryer System

The ProMate II dryer is designed for quiet and efficient operation. The color print models feature a combination heat and forced air dryer system assuring consistent and complete drying of prints.

The ProMate II black and white print models feature an infrared dryer which produces the highest gloss possible on RC photographic papers. It also enhances the sheen of semi-matte, silk, and pearl finish papers.

Cost Saving Features

Providing maximum energy and water savings, the ProMate II computer monitors material entering the processor and controls on/off times for the transport, wash water, and dryer cycle. The wash water rate can be maintained at the absolute minimum based on the actual amount of material being processed.

While in the stand-by mode, all unnecessary processor functions are shut down automatically, saving utility costs and minimizing wear.

Tempered water is not required to maintain solution temperatures which further reduces operating costs.

Applications

RA-4 Color Print:

Materials:

Ektacolor Supra II, Portra II and Ultra II

RC Papers

Duraflex RA Print Material

Duratrans RA and Duraclear RA

Display Material

Ektamax RA Professional Paper

Chemistry

Ektacolor RA

Ektacolor RA-4NP

Black and White Print:

Materials:

RC Paper

Chemistry

Designed for replenishment type developers and fixers.

Not recommended for processes utilizing an activator or for     “stabilization†type chemicals.

NOTE:Listed materials and chemicals are KODAK registered trademark products. Equivalent products from other manufacturers may also be used. Contact your Kreonite Dealer for additional information.